Commercial Kitchen Flooring- Best Epoxy Upgrade

After years of the wrong coatings installations, the the owner of the famous Mystic Diner in Mystic, CT decided to end all the mistakes by contacting Mike Osgood, owner of DiamondKote Resurfacing. John from Mystic Diner liked the many positive reviews and 24 years of experience that DiamondKote brought to the table (pun intended!). Upon the first walk through, Mike discovered extreme failure due to improper concrete prep and the use of the wrong materials by other “professional” epoxy companies. There were areas that just peeled up and there were many strange holes from 1/8″ to 2″ around that were suspicious.

We began Prep with our diamond grinding machines with vacuum assist. We were able to cut through the bad areas and get to the root of the problem. We found that the original installers did not prep the concrete properly by grind the cream layer down and exposing the open pores in the concrete surface. A proper surface profile with a scratch pattern from the diamond grinding and using the correct material would have prevented this failure.

Proper Concrete Profile

After the floor was grinded properly, we noticed that there were oils and contaminants still in the original concrete surface that the previous installing company never removed. Over the years, these contaminants migrated up to the surface right through the multiple layers of epoxy, resulting in permanent holes in the finish product that would get filled with dirt and oils.

Oil Contamination

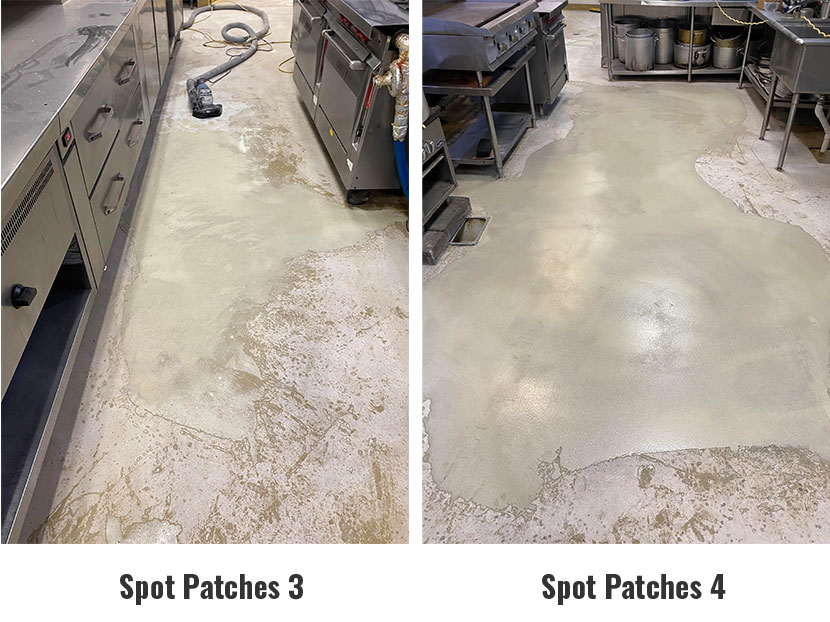

We dug out and removed the contamination and flash patched the repair areas and leveled off the floor with spot patches and blended in the edges so they aren’t noticeable in the finish product.

After these areas cured, we applied our 3/6″ thick ProKRETE SLB urethane cement system with Urethane top coats. It provides a heavy duty wear and heat resistant system that Epoxy can’t handle. Since a full shutdown of the restaurant was necessary during the installation, the Mystic Diner owner opted to got with ProREZ ProSPARTIC fast setting polyaspartic urethane top coats to cut the installation time down from 1 week to a total of 3 days, saving thousands in revenues.

The color choice was ProREZ Sand Color to brighten up the floor and blend in with the rest of the kitchen and storage areas. The finish product is a durable, stain resistant 1-color finish with an 60 grit sand paper finish for excellent wet traction but still easy to clean.